Stress corrosion cracking (SCC) is difficult to predict and identify, and can lead to catastrophic failure, often without any prior warning. Element’s stress corrosion cracking testing can help to evaluate the susceptibility of metallic materials to cracking. We quickly determine the size and scope before the failure occurs, avoiding high industrial costs and safety hazards.

What is Stress Corrosion Cracking and why is Testing Important?

Stress corrosion cracking (SCC) is the unexpected sudden failure of standard ductile materials when exposed to the combined effects of sustained tensile stress and corrosion. It can occur with static externally applied loads and residual stresses from welding, forming, machining, grinding, physical damage, heat treatment, and operating pressures. As SCC often develops rapidly, without prior warning, and can lead to catastrophic failure, it is crucial to test for potential issues before they occur.

Key Benefits of Stress Corrosion Cracking Testing at Element

- Compliance Assurance: Meet stringent industry standards, regulations and accreditations, such as NACE, BS, ISO, ASTM and NADCAP, ensuring regulatory compliance and reliability.

- Industry-Specific Expertise: Leveraging our industry-specific knowledge, we offer stress corrosion tests for metals and alloys used in key sectors like Energy, Aerospace, and Transportation.

- Global Reach and Accessibility: Access SCC testing services globally, even in remote or offshore locations, regardless of your business's geographic presence

- Cost-effective and Timely Solutions: Emphasize safety and reliability while maintaining high quality, our services are fast and efficient to manage your costs effectively.

- Advanced Testing Techniques: With state-of-the-art equipment and advanced technology, we can ensure accurate and reliable stress corrosion cracking assessments, even for complex structures and materials.

- Customized Testing for Diverse Environments: Experience tailored testing protocols and large capacity simulation facilities replicating diverse operating environments like onshore, offshore, harsh climates, high altitudes, high pressure, road, rail, or maritime.

- Predictive Testing for Long Service Life: Crucial for maintenance and safety planning, our accurate predictions of material degradation over extended periods ensure a comprehensive understanding of material performance throughout the life cycle.

- Diverse Materials Testing: Benefit from testing a wide range of materials prone to stress corrosion cracking, including carbon and alloy steels, stainless steels, nickel alloys, aluminum alloys, titanium alloys, and copper

- Chlorine-Induced Stress Corrosion Testing: For those in the Nuclear industry, access reliable and safe chloride-induced stress corrosion testing adhering to ASTM standards, addressing specific industry needs.

Early Detection and Prevention

Stress corrosion often develops rapidly in a structure. It’s difficult to predict and can lead to unexpected failures. Stress corrosion cracking testing with Element identifies significant threats such as external and internal corrosion, manufacturing defects, welding and fabrication defects, equipment failures, and incorrect operations. Our testing detects these risks early, preventing costly expenses, safety hazards, and damage to the environment and your company’s reputation.

Comprehensive SCC Testing Services and Capabilities

We offer comprehensive stress corrosion tests for metals and alloys, including:

- Carbon and alloys steels

- Stainless steels

- Nickel alloys

- Aluminum alloys

- Titanium alloys

- Copper alloys

Chlorine-Induced Stress Corrosion Testing

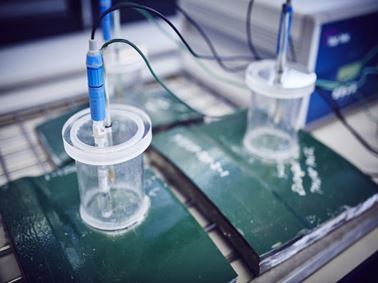

Chloride stress corrosion cracking is a type of intergranular corrosion that is particularly important to the nuclear industry. It occurs in austenitic stainless steel under tensile stress when exposed to oxygen, chloride ions, and high temperature. Element provide reliable and safe chloride-induced stress corrosion testing using a chloride-containing environment in accordance with ASTM G-36-94.

Why Choose Element?

Element operates a worldwide network of corrosion testing laboratories accredited to ISO 17025 and NADCAP, with locations across the United States, Europe, the Middle East, and Asia. We perform a wide range of stress corrosion cracking testing in a variety of environmental conditions, covering both in-field inspection and laboratory analysis.

With more than ten years of expertise in delivering corrosion testing services, we have assisted various industries, including Oil and Gas, Aerospace, Transportation, and many others.

Combining extensive industry knowledge with cutting-edge laboratory testing and simulation facilities globally, we take pride in delivering certainty in sectors where failure is not an option.

Find out more about Element and our credentials within the testing, inspection, and certification industry.

For more information about how we perform Stress Corrosion Cracking (SCC) Testing, or to request a quote, contact us today.

Related Services

Hydrogen Induced Cracking (HIC) Testing

Element’s HIC tests evaluate material susceptibility to hydrogen induced cracking in a sour environment in accordance with NACE TM0284.

Intergranular Corrosion Testing

Find out more about Element's intergranular corrosion testing service (IGC) to help prevent deterioration of materials along grain boundaries.

Sulfide Stress Cracking (SSC) Testing

Element's SSC (Sulfide Stress Cracking) testing according the NACE TM0177/ ISO 15156 standard helps ensure sour service pipelines’ reliability and longevity.

Sour Service Corrosion Testing

Find out about Element's sour service corrosion testing services for evaluating how equipment and materials will hold up in environments rich in hydrogen sulfide and other caustic gases.