About Element Boxborough

Element Boxborough is New England’s premier EMI/EMC, Environmental, Dynamics and FAA Fire test facility with 65,000 square feet of testing area across a six-building campus.

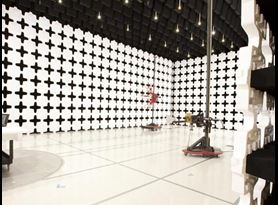

Offering everything from state-of-the-art chambers (including a 10 meter anechoic chamber) to hydraulics, dynamics, FAA Fire, NEBS, wireless, extreme environmental simulations, and more, we serve virtually every industry that requires testing services, including the defense, aerospace, space, consumer electronics, medical, telecom, transportation and automotive industries.

Element Boxborough Expertise

EMI / EMC / ESD / NEBS Testing

Element Boxborough provides EMC / EMI / ESD capabilities with expertise in testing to military, aerospace, telecommunications, electronics, nuclear, and other global industry specifications. Military and aerospace capabilities include radiated immunity testing up to 200 V/m from 10kHz to 40GHz, as well as Electrical Power Characteristics testing for ground, aircraft, shipboard, and submarine applications. Our copper lined reverberation chamber coupled with state-of-the-art amplifiers capable of meeting DO-160 Category G levels from 100 MHz to 18 GHz. Additional capabilities include lightning simulation indirect effects, and ESD up to 30kV.

Element certifies telecommunications products to network equipment building systems requirements (NEBS) as well as international standards. Element also provides complete certification of information technology, industrial and other commercial/electronic products to global EMC and product safety regulatory standards. Element Boxborough has six shielded chambers, including a three-meter and 10-meter FCC listed chambers. More EMI / EMC / ESD / NEBS details.

Environmental Testing

Boxborough is a full-service environmental test facility capable of managing your environmental test programs in the commercial, military, defense, telecom, transportation and medical markets. Our technicians and engineers are recognized experts in the performance of a wide array of environmental simulations. The lab boasts 32 temperature chambers (4 of which are walk-in temperature/humidity chambers).

Dynamics Testing

Dynamic testing is essential in a variety of products, components, and systems. This is particularly true for motorized systems, especially those intended for mass production like automobiles and airplanes, must adhere to strict operational requirements - even when subjected to various levels of vibrations, noises, pressures and other potentially disruptive forces. At the Boxborough lab, you get access to a wide range of dynamic testing services using a combination of electro-dynamic shaker systems, seismic systems, acceleration, static and dynamic loading, and more.

More Environmental and Dynamics Testing details.

Other Specialties

• Electro-Dynamic Shaker Systems

• Seismic Systems and Acceleration Services

• Shock and Drop Services

• Hydraulic Testing

• FAA Fire

• Custom Engineering Services

Boxborough Featured Services

Environmental Testing

Element can provide you with critically important data on your product or part's performance in response to typical or extreme environmental stresses and conditions.

NEBS & Telecoms Infrastructure Testing

Assure emergency network reliability for a variety of common incidents, such as earthquake and fire.

Dynamics Testing

In addition to vibration testing, Element provides a range of dynamics testing including acceleration, shock, drop, structural, fatigue and rotating load simulations.

EMC Testing Services

Find out how Element delivers electromagnetic compatibility testing (EMC) solutions to RTCA/DO-160, MIL-STD-461 and Def-Stan 59-411 standards.

Our team of over 9,000 Engaged Experts in North America, Europe, The Middle East, Australia, Asia and Africa are ready to help you.

Element Boxborough Expertise

EMI/ EMC/ ESD/ NEBS Testing Details

We perform virtually every type of electromagnetic test you need, including:

• Radiated Susceptibility ~ 200 V/m (Frequency Range 10 kHz to 40 GHz)

• HIRF Testing 100 MHz – to 18 GHz up to 7200 V/m pk

• Radiated Emissions ~ 30 Hz to 40 GHz

• 3-Meter Semi-Anechoic Chambers

• 10-Meter Semi-Anechoic Chamber

• 9 MIL/AERO Semi-Anechoic Chambers

• Reverberation Chamber 100 MHz to 40 GHz

• Extended Ground Plane Test Beds

• Indirect Lightning-Single Stroke, Multiple Stroke, Multiple Burst, Level 5 DO-160

• AC & Telecom Port Surge

• Electrical Fast Transients, Ring-Wave, and Bust Testing

• Electrical Power Characteristics testing

• Airborne Acoustic Noise and Structure-Borne Noise

• Antenna Characterization

• Shielding Effectiveness and Transfer Impedance

• Electrostatic Discharge Up to 30 kV

• Electromagnetic Pulse (EMP) to 50 kV/m

• HERO

• RADHAZ Analysis

• AC Power Fault

Verizon ITL Approved NEBS Test Lab

Element certifies telecommunications products to NEBS as well as international standards. We provide complete certification of information technology, industrial and other commercial electronic products as well as global EMI/EMC and product safety regulatory standards. In addition, Element Boxborough lab is one of several Element facilities to hold Verizon ITL certification for environmental and dynamic testing.

Environmental & Dynamic Testing Details

Boxborough is a full-service environmental test facility capable of managing your environmental test programs in the commercial, military, defense, telecom, transportation and medical markets. Our technicians and engineers are recognized experts in the performance of a wide array of environmental simulations.

The lab boasts 32 temperature chambers (4 of which are walk-in temperature/humidity chambers).

Key environmental test highlights include:

• 32 Temperature and Humidity Chambers from 2′ x 2′ x 2′ to 12'L x 10'W x 9'H

• 8′ x 8′ x 10′ Temperature/Altitude Chamber to 40,000 ft.

• 4′ x 4′ x 4′ Temperature Altitude Chamber Up to 70,000 ft.

• Salt/SO2 Fog Chambers

• Wind Driven Rain to 70 mph

• Icing/Freezing Rain/Snow

• Fire Resistance and Needle Flame for NEBS

• 20′ x 20′ Fire Chamber

• Explosive Atmosphere

• Settling Dust Chamber

• Solar Load and Heat Load Tests

• HALT/HASS Testing from -100°C to 200°C and to 50Grms (5-5,000Hz)

Dynamics Testing

Dynamic testing is essential in a variety of products, components, and systems. This is particularly true for motorized systems, especially those intended for mass production like automobiles and airplanes, must adhere to strict operational requirements - even when subjected to various levels of vibrations, noises, pressures and other potentially disruptive forces. At the Boxborough lab, you get access to a wide range of dynamic testing services using a combination of electro-dynamic shaker systems, seismic systems, acceleration, static and dynamic loading, and more.

Electro-Dynamic Shaker Systems

Notable electro-dynamic shaker systems include:

• ETS I1045M: 22000 Sine and Random, 44,000 Shock, Frequency Range 1 to 3000Hz

• LDS V895: 12,500 Force Pound, Frequency Range 1 to 3000Hz (can run srs shock up to 10,000Hz)

• T1000A: 19,000 Force Pounds, Frequency Range 4 to 3000Hz (can run srs shock up to 10,000Hz)

• T1000B: 10,000 Force Pounds, Frequency Range 4 to 3000Hz (can run srs shock up to 10,000Hz)

• T2000: 25,000 Force Pounds, Frequency Range 1 to 3000Hz (can run srs shock up to 10,000Hz)

• T4000A: 40,000 Force Pounds, Frequency Range 1 to 3000Hz (can run srs shock up to 10,000Hz)

• T4000B: 28,000 Force Pounds, Frequency Range 4 to 3000Hz (can run srs shock up to 10,000Hz)

• Team Table: 14,000 Force Pounds, Frequency Range 1 to 500Hz

Seismic Systems and Acceleration Services

At the Boxborough lab, you can get seismic simulations using 16 KIP 10″ stroke, 40″/second, 4′ square tables. In addition, you can measure the stress of your product or component using the lab's acceleration system, which includes a 40″ Arm that can reach 100g.

Whether you need static or dynamic loading, you can get the test set up that works for you.

Shock and Drop Services

• Multiple Shock Towers with Half-Sine/SRS simulation

• Drop Tester for packaged and unpackaged drops - 12" to 72" heights

Other Specialties at Element Boxborough

Hydraulic Testing

Key hydraulics testing services include:

• Endurance

• Burst and Proof Pressure

• Cracking and Reseat Pressure

• High and Low Temperature (Fluid and Environment)

• Leakage

• Static Pressures to 30,000 psig

• Temperatures from -55°C to 135°C

• Flows of 20 GPM

We conduct hydraulics testing to meet the standards and requirements of the following leading organizations:

• American National Standards Institute (ANSI)

• International Organization for Standardization (ISO)

• Radio Technical Commission for Aeronautics (RTCA)

• Society of Automotive Engineers (SAE)

FAA Fire

FAA fire testing is often conducted to meet different specifications. At the Boxborough lab, we commonly test to the following specifications:

• RTCA DO-160 Section 26

• ISO 2685

• FAA AC20-135

• FAA Powerplant Engineering Report No. 3A

• FAR Part 25

Custom Engineering Services

With engineers who sit on advisory boards, author technical papers, and shape industry standards, you get access to experts who can customize any type of test. As a result, we can assist you with providing a product assessment, defining the proper requirements for design, outlining the test program, and providing quality verification to achieve maximum customer acceptance, and saving money.

International Approvals and Certification

Getting your product into international markets can be difficult with geopolitical dynamics fundamentally impacting the type of markings you might need to get your product into a new country. Our team of experts is dedicated to helping you secure regulatory approval in global markets with a streamlined process designed to avoid delays and duplicative testing. Our international approval services include:

• A Single-Point-of-Contact for 180 Countries

• In-country Testing and Approvals

• Globally Recognized Test Reports

• In-Country Representation

• On-going Compliance Tracking

• Compliance Strategy for Faster Certification