About Element Tempe

Element Tempe is your comprehensive testing location for climatic simulations, dynamics, and EMI/EMC test services in Arizona. We deliver expertise for both the commercial and military sectors all the way from full qualification programs to early-stage design verification and R&D efforts.

Our competencies extend to dynamic evaluations, encompassing vibration, shock, SRS, and acceleration tests. In the realm of climatic simulations, we provide temperature, humidity, and altitude assessments. Notably, we stand as a Center of Excellence for solar radiation testing, adhering to the stringent MIL-STD-810 standards Procedures I and II. Our EMI/EMC capabilities cover emissions, susceptibility, and high-power RF testing. As Arizona’s leading testing facility, Element Tempe upholds a commitment to precision, leveraging its vast experience, specialized expertise, and state-of-the-art equipment.

Element Tempe Expertise

Environmental Testing

At Element Tempe, our capabilities extend to replicating the most intricate conditions encountered on Earth and in space. We are equipped to recreate specific scenarios to ascertain that your product delivers optimal performance in its intended operational setting. Whether it’s simulating the drastic thermal changes that a satellite component will face or the worst-case decompression event that a piece of avionics equipment might experience, our test equipment has you covered. We cater to an expansive array of products, ensuring they are robust enough to thrive even in the most rigorous conditions.

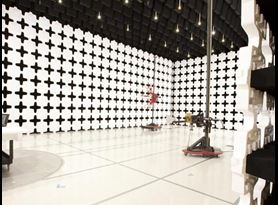

EMI/EMC Testing

Element Tempe provides world-class electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing services so your time from design to market is as efficient as possible.

Dynamics Testing

To ensure your products can withstand the extended forces caused by random and sine vibrations - as well as the intense short-term forces from shocks, drops, and accelerations—there is no substitute for comprehensive dynamics testing.

Tempe Featured Services

Vibration and Shock Testing

Element works with manufacturers from the very beginning to try and understand the implications of environmental compliance.

Solar Radiation Testing

Solar radiation testing simulates the deteriorating thermal and physical effects of UV sunlight on products and materials.

EMC Testing Services

Find out how Element delivers electromagnetic compatibility testing (EMC) solutions to RTCA/DO-160, MIL-STD-461 and Def-Stan 59-411 standards.

Sand and Dust Testing

Find out about Element’s sand and dust testing services to assess your product performance when exposed to desert sand and dust.

Thermal vacuum testing

Element's thermal vacuum testing allows for the simulation of space and upper atmosphere conditions, including temperature and altitude.

Thermal Shock Testing

From routine testing to complex, custom projects, our experts support test protocol development and specification selection for multiple types of mechanical shock testing.

Salt Spray Testing

Find out how our Engaged Experts conduct salt spray testing, or natural salt spray (NSS) to evaluate the integrity of a coating in a corrosive environment or to test the corrosion resistance of a product or material.

Dropped Objects Testing

Ensure dropped object prevention equipment functions safely and as designed with Element's testing services to ANSI/ISEA 121-2018 standards.

Our team of over 9,000 Engaged Experts in North America, Europe, The Middle East, Australia, Asia and Africa are ready to help you.

Environmental Testing

Temperature/Humidity Chambers

• From 2′ x 2 ‘ x 2′ to a 4′ x 6’x 8’ Walk-In Chamber

• Humidity up to 95%

• Temperature ramp rates up to 30C/min

Thermal Shock

• -185C to 200C

• Up 24”x24”x24”

• Liquid to Liquid Thermal Shock (6”x6”x6” Basket)

Altitude

• Up to 100,000 Feet

Combined Environments (Temperature, Altitude, and Humidity)

• 36”x36”x40”

Thermal vacuum

• -180° to 175°C Space Simulation

• 1×10-5 Torr

• Multi-Zone Temperature Control Chambers

• 33”x33” Platen and Up to 36” High

Rapid and Explosive Decompression and Overpressure

Explosive Atmosphere

Fluid Susceptibility Testing

Dust and Water Ingress (IP testing)

Blowing Sand and Dust

• Dust Storms up to 40mph

Rain and Wind

• Wind-Driven Rain up to 40mph

Salt Fog

• Salt-fog, salt spray, and Cyclic Corrosion Testing.

Solar Radiation

• Three Walk-in Chambers with Irradiated Area Up to 20 Square Feet

• Heating Effects (MIL-STD-810 Procedure I)

• Actinic Effects (MIL-STD-810 Procedure II)

Primary Specifications

• MIL-STD 810

• MIL-STD 202

• RTCA DO160

• ASTA

• ASTM

• NEMA

• GR 63-CORE

• GR 487-CORE

• GR 13-CORE

• UL 50

• ETSI 300-019-xx

• IEC 60068-2-xx

EMI/EMC Testing

Element Tempe provides world-class electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing services so your time from design to market is as efficient as possible.

We offer EMI/EMC testing services to help our clients’ products meet a broad range of industry and government standards, namely RTCA/DO-160 and to MIL-STD-461 regulations. Fully backed by our ISO/IEC 17025 accreditation, our EMI/EMC services include:

• Radiated Susceptibility (10 kHz to 40 GHz, 200V/m)

• HIRF Testing 100 MHz to 18 GHz and Up to 7200 V/m pk

• Radiated Emissions from 30 Hz to 40 GHz

• MIL/AERO Semi-Anechoic Chambers

• Reverberation Chamber 200 MHz to 18 GHz

• Extended Ground Plane Test Beds

• Indirect Lightning-Single Stroke, Multiple Stroke, Multiple Burst (DO-160 Level 3, MIL-STD-461 Internal Equipment Levels)

• Electrical Power Characteristics Testing

• Airborne Acoustic Noise

• Shielding Effectiveness, Transfer Impedance

• Electrostatic Discharge Up to 30 kV

• HERO

• USCAR-28 and AK-LV-16 compliance testing for airbag initiators

Primary Specifications

• RTCA/DO-160

• MIL-STD-461

Dynamics Testing

To ensure your products can withstand the extended forces caused by random and sine vibrations - as well as the intense short-term forces from shocks, drops, and accelerations—there is no substitute for comprehensive dynamics testing. Element Tempe’s wide selection of dynamics, vibration, shock, and acceleration capabilities includes:

Electrodynamic and Mechanical Shaker Systems

• Up to 24,000 Force Pounds

• 5 Hz to 3000 Hz

• Up to 3" pk-pk Displacement

ETS I1045 Shaker System Vibration

• 24,000 lbf, 220 g, 2” pk-pk Displacement, Up to 80”/sec Velocity

• Shock 44,000 lbf, 3” pk-pk Displacement. Up 180”/sec Velocity

• 480kVA Amplifier

• 1,520 Pound Max Static Payload

Acceleration

• 3 centrifuges with arm radius lengths of 57, 36, and 11-Inches

• Up to 1,200 Gs

• Up to 40 Slip-Rings for powered and functional testing

Drop Towers

• Multiple drop towers with up to 45-Foot Drop

• Package drop machines

Primary Specifications

• MIL-STD 810

• MIL-STD 202

• RTCA DO160

• ISTA

• ASTM

• UL 50

• ETSI 300-019-xx

• IEC 60068-2-xx