Our composite fatigue testing service is designed to help you unlock the full potential of your materials. We understand that you need reliable and safe products that perform well over time, and that's exactly what we deliver. Our team of experts provides tailored solutions to help you achieve heightened product reliability, increased safety standards, and improved design efficiency.

What Is Composite Fatigue Testing?

Composite fatigue testing evaluates the properties of the material when subjected to cyclic loading over time. Composite fatigue testing varies from fatigue testing of metals because composite fibers are oriented, which means the fatigue properties depend on direction, layup, and failure mode.

Generally, fatigue properties are not a critical consideration for fiber-dominated materials, as fatigue cracks arrest when reaching the next fiber. However, certain highly fatigued parts or structures, like rotor blades or propellers, are an exception. For these components, composite fatigue testing may be performed to better understand the fatigue life.

Benefits of Composite Fatigue Testing

- Enhanced Product Reliability: Composite fatigue testing helps identify potential failure points in materials, enabling you to design more reliable and durable products.

- Improved Safety: By uncovering weaknesses in materials early on, fatigue testing contributes to the development of safer products, particularly in industries where structural integrity is critical.

- Cost Savings: Detecting and addressing fatigue-related issues during the design phase can prevent costly failures and recalls later on, ultimately saving time and money.

- Optimized Design: Insights gained from fatigue testing allow engineers to refine product designs, optimizing material selection and configuration to maximize performance and longevity.

- Expert Guidance: With Element's experienced team of engineers and technicians, you receive expert guidance throughout the testing process, ensuring accurate and insightful results.

- Customized Solutions: Element tailors Composite fatigue testing services to meet your specific needs and requirements. We provide personalized solutions that address your unique challenges.

Expert Guidance Through Composite Fatigue Testing Complexities

We understand that navigating the complexities of composite fatigue testing can be overwhelming, especially for those who may not have extensive expertise in materials science.

Our experienced team of engineers and technicians guides you through every step of the testing process, providing clear explanations and support to ensure that you understand the testing methodology and its implications for your project. We break down complex concepts into easily digestible information, empowering you to make informed decisions with confidence.

Methods of Composite Fatigue Testing

Element offers different test methods for evaluating the fatigue properties of composite materials, including:

- Tension-tension

- Tension-compression

- Compression-compression

- Bending fatigue

- Fatigue crack growth

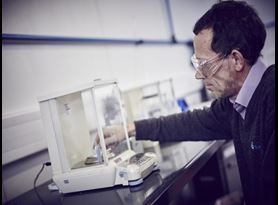

Depending on the method, fatigue tests may be performed in-plane in the fiber-dominated direction, or out of plane with interlaminar loading to assess composite damage tolerance and damage growth. Our composite fatigue testing labs have multiple load frames equipped with aligned hydraulic grips for a range of load capacities to support the different methods.

The Element Advantage in Composite Fatigue Testing

Element's global network of laboratories offers fatigue testing for a diverse range of materials and products, encompassing composites, metals, plastics, 3D printed products, and medical materials. Our experts are proficient in testing according to various standards, including ASTM D3479, and are capable of developing custom testing programs to suit your specific needs. With our commitment to accuracy and reliability, you can trust us to deliver precise results, whether you're testing to a standard or pursuing a customized approach.

To learn more about Element’s credentials, please visit our About Us page. To discuss how we can support your composite fatigue testing needs, contact an expert today.

Fatigue Testing Verifies Component Durability for Long-Term Applications

We explain how composite fatigue tests are performed, key methods, how fatigue testing of impact-damaged laminates work, & fatigue crack growth testing.

Read MOREUnderstanding Composite Compression Test Methods

Composite compression tests often follow ASTM or ISO methods. Understand the variety of methods and how they can help you with your testing requirements.

Read MORERelated Services

Tensile Testing of Composites

ASTM D3039 determines the ultimate tensile strength, ultimate tensile strain, tensile chord modulus of elasticity, Poisson’s ratio and transition strain of Polymer Matrix Composites (PMCs).

Polymers Testing

Element performs a range of mechanical, electrical, flammability tests and utilizes thermal analysis tests to characterize the composition of polymers and composite materials.

Fatigue Testing

Find out how Element's fatigue testing labs help companies meet quality requirements and create safer, stronger, more successful parts and products.

Understanding Composite Compression Test Methods

While there is no set standard for testing the compressive strength of composites, our experts can help you select the test methods that will generate the required result.