3kHz Aerospace Shaker Equipment for the European Market

In early 2019, Element Warwick is changing the landscape of European product testing by adding 3kHz aerospace vibration equipment to their already impressive range of capabilities. This new acquisition will provide quicker, lower-cost options for manufacturers who have been forced to request concessions. Element Warwick’s new capability represents the latest in state-of-the-art aerospace shaker equipment. With the ability to reach force and frequency levels previously unavailable in Europe, Element is proud to be providing our clients with greater access to testing excellence that’s closer to home.

Our Aerospace Shaker Equipment Capabilities

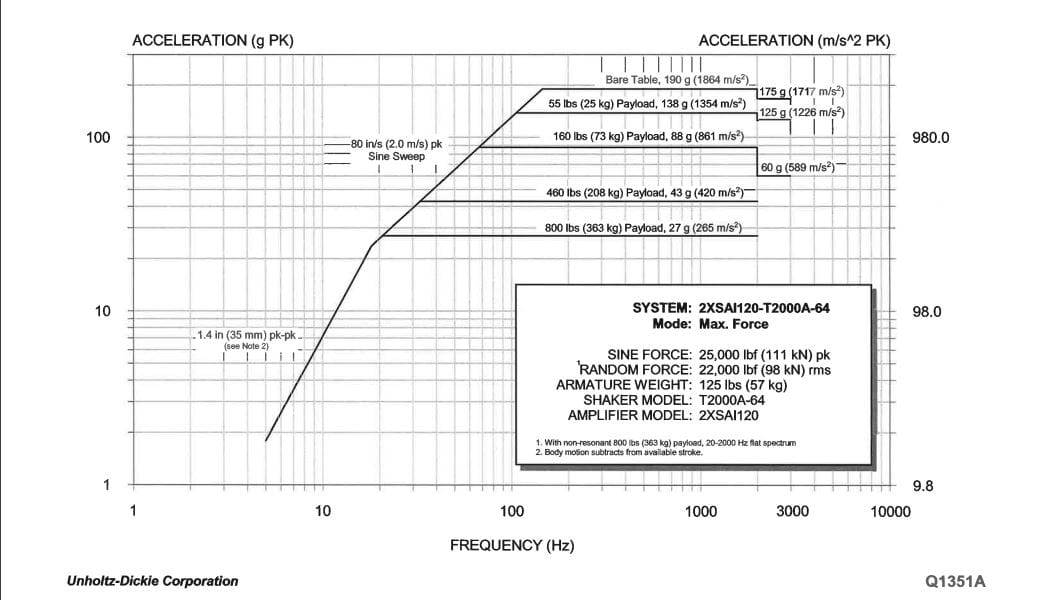

The Model 2XSAI120-T2000A has an impressive range of system output force ratings, including:

- Sine : 25,000 pounds (111 kN) peak

- Random: 23,000 pounds (102 kN) rms

- Shock: 67,000 pounds (298 kN) peak

Why is 3kHz testing important?

As aero engine manufacturers push the limits of their design, they are imposing harsher qualification regimes to ensure greater reliability of their safety-critical products.

‘On engine’ components and subsystems face the most severe environment on the aircraft, and this new shaker allows us to impose real life vibration exposure during the development and qualification process.

Most vibration systems are limited to either 2kHz or a very reduced low ‘g’ level to 3kHz, forcing customers to request concessions from the engine design authority or run tests at lower levels for significantly longer periods.

Element’s team of Engaged Experts can work with you to help meet your full range of aerospace testing requirements while helping you save time and cost.

For more information about our new 3kHz aerospace shaker equipment, or to book your project in advance, contact us today.

Find related Resources

Related Services

Our Services in Aerospace

Engaged in testing virtually every material, component and system on commercial aircraft, Element's deliverable is mission critical, certainty.

Vibration Testing

Find out how Element's vibration testing services help to make certain that the products we test for our customers will perform safely and as expected when in the field.

Product Testing

From environmental & dynamic testing to highly specialized tests such as bird strike and hydrodynamic ditching testing, we're the trusted testing partner to the world's most recognized component and system manufacturers.

Element Warwick

Our Warwick site is our European Environmental Testing centre of excellence and an SC21 signatory site, with UKAS accreditation to BS EN ISO/IEC 17025:2005.