Direct Lightning Strike Test Program

Direct lightning strike testing is a crucial part of aircraft design and qualification. Manufacturers must ensure that critical components like flight control surfaces and fuel tanks can withstand the effects of a lightning strike to avoid catastrophic failures.

This is especially true for the newest aircraft designs, where increased dependence on composite materials has made them more vulnerable to lightning strike. As a result, test standards have evolved and become more stringent. To ensure product safety, there are two major types of validation: direct strike and indirect strike testing.

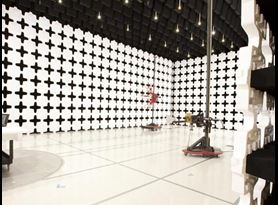

Direct Lightning Strike Testing

As the name suggests, direct lightning strike testing simulates the effects of a direct hit on aircraft or ground-based structures. Using high-powered equipment, we can test exterior materials and interior components to assess for weak areas and ensure continued performance. As the only commercially available provider of direct lightning strike testing in the UK, we provide design support, consulting and testing from start to finish.

Aircraft Lightning Strike Testing Methods

There are a variety of lightning strike test methods available, depending on the type of product being tested and the conditions being simulated. An accredited test lab can help you determine which methods will provide maximum value to your test program.Some of the methods that we offer include:

RTCA DO-160 Section 23 Requirements

High Current Testing

Our equipment can create a lightning arc which can then replicate the effects of a lightning strike to an aircraft, both in terms of physical damage at the arc attachment location as well as looking how the current distributes through the fuel system and critical structural elements.

High Voltage Testing

Our equipment allows us to replicate the initial leader phase of a lightning strike which can stress dielectric materials such as antennas, radomes, and windscreens.

RTCA DO-160 Section 22 Requirements

We can test for all waveform methods and protection levels per RTCA DO-160 Section 22. For projects with unique or custom requirements, we have the flexibility to provide virtually any waveform transient, providing coverage for a wide range of products.

Pin Injection Testing

One of the most common test methods for assessing the effects of an indirect aircraft lightning strike, this method applies lighting transients directly into the pins of electrical products and systems to determine if it causes any damage.

Cable Bundle Testing

Cable bundle tests are designed to evaluate how the effects of current flowing on cable screens and overbraids effects equipment.There are several types of cable bundle testing: single stroke, multiple stroke, and multiple burst. The single stroke method replicates the effect of the initial return stroke current on equipment while the multiple stroke method replicates the effects of successive lightning attachments to an aircraft in a short duration. Multiple burst testing is designed to replicate the effects of leaders stepping away from the aircraft which can cause upset to equipment.

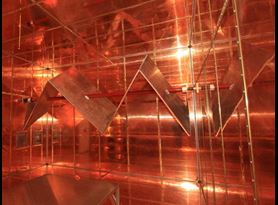

Electrostatic Testing

The increased use of composites in fuels tanks can lead to the accumulation of static. We test aircraft materials to determine if accumulated charge poses a threat to fuel tanks.

ESD Testing

We can replicate the effects of charge accumulation on munitions due to handling or from carried by helicopter.

Design Support Services

Because an aircraft lightning strike can affect the integrity of every system on an aircraft, designing with protective features in mind is critical.

An important part of the design and qualification process of the avionics system is to understand the magnitude and types of transients. We use two methods, often in conjunction, to aid in design/qualification: Computational analysis to predict the Equipment Transient Design Level (ETDL) and full vehicle testing, at low current, to determine the Actual Transient Level (ATL).

Our testing services are fully compliant to sections 22 and 23 of RTCA DO-160, MIL-STD-461 and DEF STAN 59-411, making Element the UK’s sole provider of direct lightning strike testing.

For more information about our lightning strike services, speak to an expert today.

Find related Resources

Related Services

EMC Testing Services

Find out how Element delivers electromagnetic compatibility testing (EMC) solutions to RTCA/DO-160, MIL-STD-461 and Def-Stan 59-411 standards.

RTCA DO-160 Testing

Working with Element, our clients enjoy access to the most comprehensive EMC and environmental testing capacity of any independent Aerospace product qualification testing company in the world.

Indirect Lightning Testing

Complementing our HIRF and power quality tests, our indirect lightning testing services can provide virtually any waveform transient required for compliance.

Our Services in Aerospace

Engaged in testing virtually every material, component and system on commercial aircraft, Element's deliverable is mission critical, certainty.