Fracture Mechanics Testing Download

Applying fracture mechanics to predict pipeline cracking and failure

Defects arising from manufacturing processes are found in all metal structures. Although not all such defects are unstable during construction, operating conditions such as ground movements, stresses, and harsh environments often leave pipeline systems prone to cracks. If left undetected, these forms of damage can lead to the failure of the pipeline system, which may have catastrophic consequences.

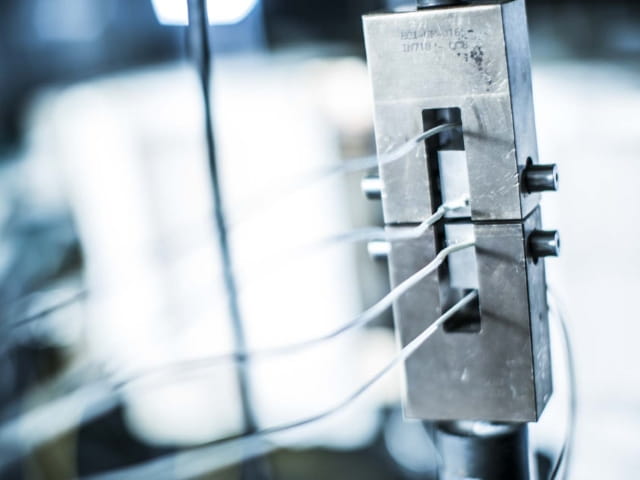

Fracture mechanics is one of the most suitable methods for assessing the reliability of pipelines. It measures the resistance of metallic materials to fracture in the presence of a known flaw and determines which flaws are critical for causing the failure of the flawed structure.

The article provides an understanding of the different test methods and sample geometries used to determine fracture toughness.

To learn more about fracture mechanics testing, please complete the form below and download our free article.

Find related Resources