For projects that require accurate dimensional measurements, Element offers a broad range of 2D and 3D metrology services.

From tool and die inspection to reverse engineering, Element's dimensional measurement services can help you optimize production processes, correct component problems and improve quality control.

What is a dimensional inspection?

Dimensional inspection captures the geometric shape of workpieces in two or three dimensions, the components produced must adhere to precise dimensions using quantifiable values to measure any physical characteristics such as: Length, width, and height, showing only minimal deviations from specifications to ensure functionality and reliability.

The results are compared with drawings or CAD models to determine target/actual deviations and subsequently compiled into professional, detailed reports.

Dimensional inspection services

Large or small, 2D or 3D — Element has the precision machines and tools to accurately measure everything from complex geometries and surfaces to curves and straight lines. We maintain an exceptionally clean and stable laboratory environment to ensure total quality control. Our advanced dimensional inspection and metrology services include:

- 3D CMM inspection and photogrammetry for tactile and optical inspection of components.

- industrial computed tomography for components with complex geometries.

- laser tracking for 3D scanning of very large components such as rotor blades and structures.

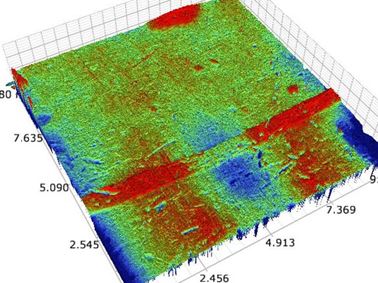

- optical profilometry for surface roughness measurement

- non-destructive testing and inspection

Applications for metrology and dimensional inspection

Our 3D metrology and dimensional inspection support a wide range of industries and applications, including CAD drawings, machined parts, medical devices, upscale contours, tool wear monitoring, tools and fixtures, castings, and forgings, fasteners, printed circuit boards, and injection molded parts.

Dimensional inspection methods and approaches

- Tooling and Mold Inspection: As part of your manufacturing process, we help to monitor tool wear and quality control.

- First article inspection: Our metrology laboratories provide fast, accurate first article inspection and verification of your design and manufacturing processes.

- Reverse Engineering: Element's experts can create the engineering data files required for accurate reproduction from models or modified parts or undocumented components.

- Mold Qualifications: Fragile or small parts are no problem for us. Using specialized techniques and materials, our experienced inspection experts can quickly determine accurate dimensions under the most adverse design conditions without destroying your part.

Contact us for more information about our metrology procedures or to request a quote.

Our Services

Discover our dimensional inspection services

CMM Inspection and Measurement Services

Element offers Coordinate Measuring Machine (CMM) inspection to allow the precise measurement of a wide range of components.

3D Scanning by Laser Tracking

Element offers laser tracking and 3D laser scanning services for dimensional inspections of large components.

Surface Roughness Testing

Element uses optical profilometry to measure the surface roughness of components.

Industrial Computed Tomography

Element offers high-resolution industrial computed tomography to provide a detailed examination of components that can be used for production defect detection, dimensional inspection, and reverse engineering.

3D Measuring Services

Find out about how Element's 3D measurement services can provide a complete picture of component interaction without causing damage to your sample.

Non-Destructive Testing (NDT)

Element's NDT services comply with a wide variety of industry standards, government contracts, military specifications and unique customer requirements.