From electrostatic buildup to critical equipment failures, the effects of an aircraft lightning strike can be catastrophic. Our lightning protection testing services help ensure that, in the event of a direct strike, your electronics, equipment and materials continue to perform without failure.

While the increased use of composite materials has made more lightweight and efficient structures, it also means that equipment is more vulnerable to aircraft lightning strike. As a result, test standards have evolved and become more stringent.

Testing standards for lightning strike

Easily achieve requirements of RTCA DO-160 Section 22, MIL-STD-461 and DEF STAN 59-411. From consulting and design to final assessment, we help ensure that your equipment is safe and up to task, no matter what the project. Our aircraft lightning strike services also cover variety of commercial and defense specifications.

Element's aircraft lightning strike test methods

We have the capability to test for all waveform methods and protection levels per RTCA DO-160 Section 22. For projects with unique or custom requirements, we can we have the flexibility to provide virtually any waveform transient, providing coverage for a wide range of products. Some of our methods include:

- Single stroke pin injection testing

- Single stroke cable bundle testing

- Multiple stroke testing

- Multiple burst testing

For more information about our lightning strike test methods, or to request a quote, contact us today.

Fuel systems and structures testing

Aircraft lightning strike testing helps safeguard fuel tanks and systems against ignition hazards caused by a strike. Our services include high-voltage generators for photographic testing, ignitable mixture testing, and transient hot spot measurements.

Electrostatic testing

The increased use of glass fiber composites in aircraft design can lead to the accumulation of static electricity. We test aircraft components to determine if accumulated charge poses a threat to fuel tanks or electrical systems.

Additional Electronics Test Methods

In addition to lightning protection testing, we offer a range of mechanical, environmental and electrical that affect the integrity and performance of on-board electronics, including:

- Sand & dust testing

- Vibration testing

- Combined environmental testing

- HALT/HASS testing

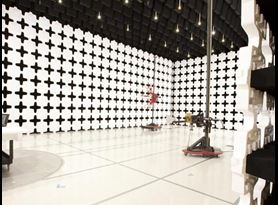

- High-Intensity Radiated Field (HIRF) testing

- Operational reliability testing

Interested in knowing more? To request a quote or additional information, get in touch with an expert today.

More from Element

EMC Testing Services

Find out how Element delivers electromagnetic compatibility testing (EMC) solutions to RTCA/DO-160, MIL-STD-461 and Def-Stan 59-411 standards.

Our Services in Aerospace

Engaged in testing virtually every material, component and system on commercial aircraft, Element's deliverable is mission critical, certainty.

Environmental Testing

Element can provide you with critically important data on your product or part's performance in response to typical or extreme environmental stresses and conditions.

Element Locations

Learn more about our laboratories - where they are located; the unique capabilities they have and how they can help you solve your technical and commercial challenges.