The most important part of automotive circuit board development is creating a safe and compliant end product. Element’s IPC-A-610 certified circuit board testing procedures provide you with certainty that your printed circuit boards (PCBs) are evaluated in accordance with IPC standards.

Element’s reliable circuit board visual examination and cross section evaluation help you ensure the quality of your product, and in turn, save you time and money by reducing failures.

Element’s circuit board testers use IPC-A-610 to visually assess any degradation in the following:

- mechanical integrity

- solder cracking

- burn marks and discoloration

- foreign object debris

- whisker formation

- dendritic growth

- flux residue on printed circuit boards

Additionally, Element conducts cross-sectioning of PCBs to detect solder joint cracks, voids, lamination defects, poor wetting, land lift, and insufficient solder fill.

For more information on Element’s printed circuit board evaluation or to request a quote, please contact us today.

Learn more

Electronic Components Testing

Find out how Element's comprehensive services can help you bring innovative electronic systems to market that will interact safely and seamlessly with other electrical components and accessories.

Automotive Lighting Testing

Our automotive lighting testing services ensure compliance of your lighting and signaling devices to the relevant regulations, including GMW 3172.

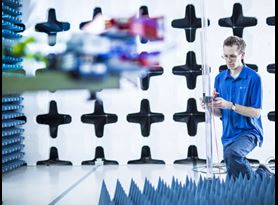

EMI & EMC Testing

Element performs electromagnetic compatibility (EMC) and electromagnetic interference (EMI) testing for a variety of medical devices and components, including implantable devices, diagnostic tools and therapeutic equipment.

Sand and Dust Testing

Find out about Element’s sand and dust testing services to assess your product performance when exposed to desert sand and dust.