Fatigue Failure: How Can You Tell?

Fatigue was not always well understood in the engineering world. It was long thought that if a material was deformed within its elastic range it would not carry any of the residual stresses or deformation when the stress was removed.

We now know that fatigue failure is an extremely important design consideration in a variety of industries, including Aerospace, Transportation, Oil & Gas, Medical Devices, and more.

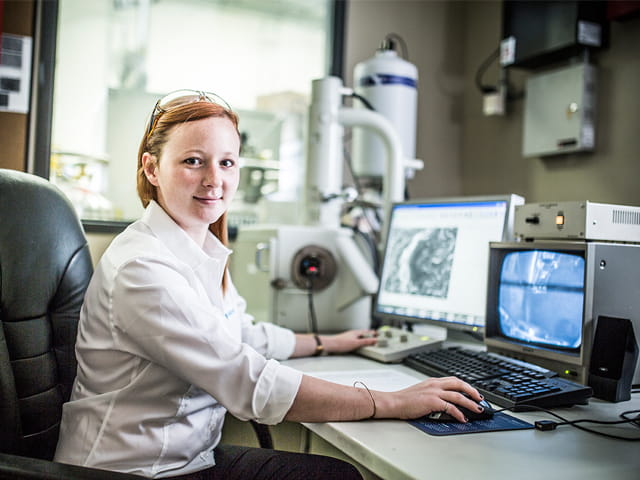

How do I know if I have a fatigue failure?

Let’s assume that your product has experienced a failure of some sort. What might indicate the nature of the failure? If we look at the broken component, we can first look for a brittle or ductile failure mode on the fracture surface. In metals, a ductile failure is generally indicative of static failure. Conversely, fatigue in metals often causes a brittle fracture. In the simplest terms, in a ductile failure, there will often be a large deformation or deflection within the part. This deformation gives an advance warning of imminent failure.

Fatigue failure occurs based on crack formation and crack propagation. As a crack initiates, it may be hard to notice much change until the crack size reaches a critical limit. By then it may be too late. A quick analysis of the fracture surface of a fatigue failure will often show features casually referred to as “beach marks”. These indicate the propagation of the failure from the initial cracks. Once the crack size has reached a critical level, it will propagate very rapidly until the fracture is complete.

How do I design against fatigue failure?

A few of the most important factors are material selection, stress concentration, surface finish, and material discontinuities.

- Material selection is paramount to all design considerations. Material selection may be limited by any of a number of factors including economic, environmental, and service restrictions. Selecting a material with a high endurance limit is good practice.

- Stress concentration is another key factor. Essentially, all sharp corners should be made into a radius if at all possible. Sharp corners provide stress concentration and are often responsible for the initial crack.

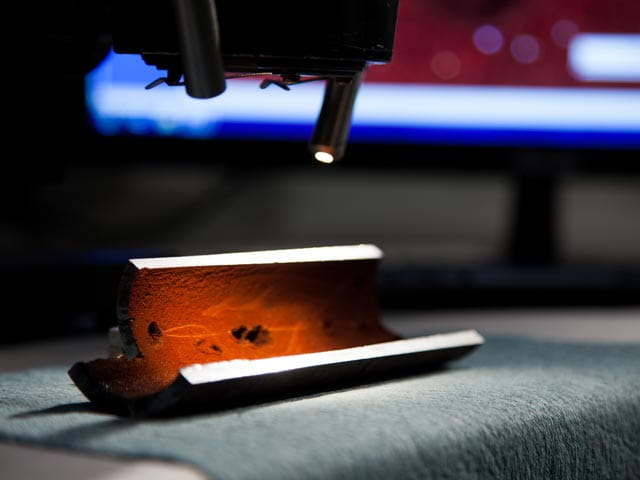

- Surface finish is another critical component. Strength of Materials classes teach a very important lesson: in many loading configurations, like bending and torsion, the critical stress is located on the surface. Therefore, a blemish-free surface will generally lend itself to good fatigue life.

- Lastly, material discontinuities are inevitable on the microscopic level, but a good forming process will help to reduce them.

It is important to keep in mind the factors that affect fatigue failure the most and, if necessary or economically feasible, produce a conservative design. Conservative designing usually takes into consideration a “worst-case scenario”. In this instance, designers usually assume fully reversed loading and often consider the Modified Goodman design criterion with a modest factor of safety when determining a theoretical endurance limit. Once the theoretical service life is determined and the part comes to fruition, mechanical fatigue testing is the next step for product verification in the design cycle.

For more information about our fatigue testing services, contact our experts today.