For engineers designing track, bending stress and fatigue testing play a critical role in validating the structural dynamics of rail and fastening systems and their ability to support the consistent weight encountered by both freight and passenger railroads. Selecting materials with the strength to withstand heavy loads, and the flexibility to allow for adequate bending, is critical to preventing failures and essential to developing the next generation of rail technology.

Our Engaged Experts have years of experience in transportation and rail testing, and we understand the unique challenges that face the industry. We work with you to validate your designs, while implement bending stress, cyclic fatigue and mechanical testing programs that accurately characterize your materials and products, helping you understand their limits, predictable lifespan and overall durability.

Slow Bend Testing Capabilities: 4 Point Flexural

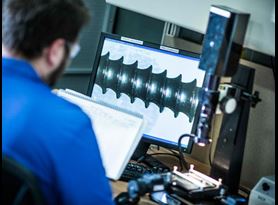

Slow bend testing is used to test the ultimate strength of concrete ties, and most importantly, to validate rail weld integrity. Using 5 ft (1.52 m) sections of rail, we focus bending stress on the center of the weld up to 750 kips. Once testing is complete, and if the weld hasn’t completely sheared, we examine the rail for cracks and surface defects. If it’s determined that more investigation is needed, we immediately perform multiple industry-specific metallurgical tests to help determine the root cause of failure.

4 point flexural testing is critical to helping us determine weld integrity and is an important part of our ability to support the rail material selection processes for major railroad companies.

Cyclic Fatigue Testing: Dynamic and Static

One of the most important criteria for railroads is the ability of rail and integrated fastening systems to withstand repeated loads. Our fatigue testing capabilities allow us to test fully assembled sections of railroads for rolling fatigue simulation. Using a one-of-a-kind train simulator specifically designed for AREMA Chapter 30 section 4.9 sub-section 2.7 Test 6, we can provide static and dynamic testing up to 120 kips From rail, to fully assembled fastening systems, our state-of-the-art test frames can test virtually any rail component.

Our bend testing capabilities and fatigue frames, coupled with our rail expertise, metallurgical lab and highly-qualified technicians, means we can provide the most accurate simulations available in the industry. In the end, ours is a complete customer-centric solution focused on supporting the expansive needs of your railroad projects.

For more information about our bending stress rail testing services, or to request a quote, contact us today.

Our Rail Testing Services

More from Element

Rail Fastener Testing

From concrete rail ties to complex fasteners, we provide longitudinal restraint testing, repeated load testing, and other strength for rail products.

Dynamics Testing

In addition to vibration testing, Element provides a range of dynamics testing including acceleration, shock, drop, structural, fatigue and rotating load simulations.

Product Testing

From environmental & dynamic testing to highly specialized tests such as bird strike and hydrodynamic ditching testing, we're the trusted testing partner to the world's most recognized component and system manufacturers.

Element Pointe Claire

Pointe-Claire is an ISO, SCC and Nadcap accredited lab providing metallurgy and fatigue testing for aerospace, rail and transportation markets.